While I acknowledge the expectations Ellis tries to set, all the youtubers out there have me chasing a dragon looking for better and better layer aliment on my z-axis. I suspect (at least) one of you will come out of the woodwork and say your printer has better aligned layers than mine too 😭 I’m certainly not alone, but even in that thread you can find some people claiming that not everyone experiences the issue

So far, I’ve been through three iterations on my CW2:

- BMG gears with a grub screw

- BMG Integrated Drive Gear Assembly (IDGA). Press fit gear = no more grub screw

- FYSETC CNC Pom w/ Helical gears, since evidently the BMG gears can still be somewhat offset

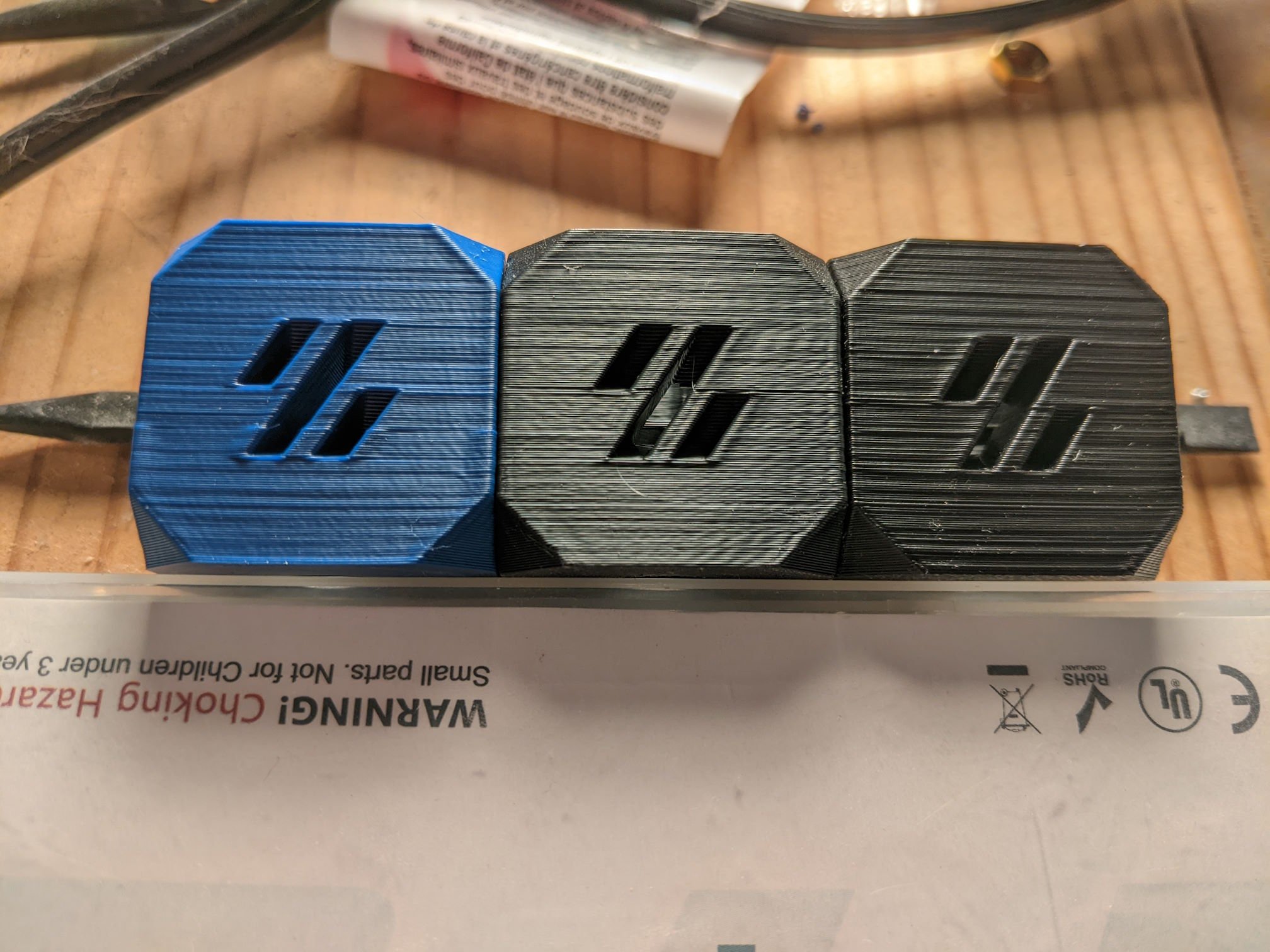

Results below with me hand holding my cellphone and moving a Pixar style desk lamp to be at a progressively steeper angle to the face of the cubes. Left = FYSTEC Pom (I also used Orcaslicer), middle = BMG IDGA, right = ‘normal’ BMGs. Note that the cubes are upside down.

Vanity shot with very soft and indirect light

Direct light, 90 degrees to the face of the cubes (basically perpendicular)

Direct light, ~45 degrees to the face of the cubes

Direct light, ~5 degrees to the face of the cubes (basically parallel)

At this point, I am going to shrug, give up, and print with fuzz (or avoid harsh light).

Extrusion variance and bad tolerance filament will also exhibit the exact same looking issues, not just poor Z alignment.

Just to be sure, you have z-hop disabled? That can cause all kinds of issues if the gantry isn’t absolutely perfect.

Another thing would be making sure all variable line width printing options are disabled, I.e ones that try to fill gaps with thicker lines or print thinner lines faster to stretch the filament.

And finally, melt temperature oscillations, making sure every feature - outer/inner walls and infill - are printed at the exact same, slower, speed.

As for actual z issues, if the bed/gantry isn’t freely moving and has even a slight bind on the screws/axis, it can miss microsteps. One rather harsh troubleshooting tip is to reduce z-microstepping to a lower value, as that gives it more torque per step and usually you do not need the z to move anywhere near as gradually as some microstepping setups theoretically might allow.

Extrusion variance is one of the reasons why I was focusing on my extruder. I’ll have to try a different brand of filament though. I’ve been printing more or less exclusively in Pokymaker ASA. It’s cheap, and prints well enough, but I can’t find tolerance info on it.

Z-hop is not disabled, I’ll have to give that a shot. This is a Voron 2.4, which has geared and belted Z. I’ll have to do the math to see what the actual resolution per full step is later tonight.

I’ve given the gantry a once over twice now and everything seems square/right and moves freely.

Right now I’m thinking my order of attack will be:

Also check if you have TMC drivers and if they have Stealthchop enabled, it can cause these types of issues. Especially for the extruder motor.

They’re TMC2209 drivers. Looking through my printer.config, I think stealthchop is disabled on all my motors. They each have this entry:

stealthchop_threshold: 0